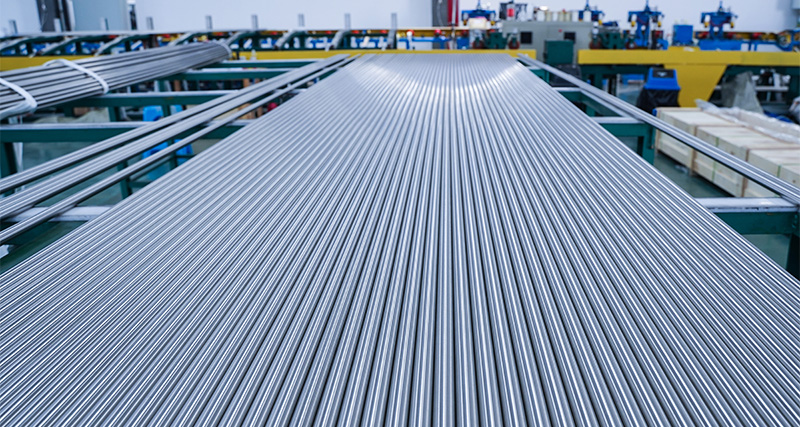

Bright Annealed(BA) Tube mara kyau

Bayanin Samfura

Bright annealing tsari ne na annealing da ake yi a cikin injin daskarewa ko yanayi mai sarrafawa mai dauke da iskar gas (kamar hydrogen). Wannan yanayin da ake sarrafawa yana rage iskar oxygen zuwa mafi ƙanƙanta wanda ke haifar da haske mai haske da ƙaramin oxide mai laushi. Ba a buƙatar pickling bayan annashuwa mai haske tun da iskar shaka ba ta da yawa. Tun da babu pickling, saman ya fi santsi wanda ke haifar da mafi kyawun juriya ga lalata.

Maganin mai haske yana kula da santsi na shimfidar da aka yi birgima, kuma ana iya samun haske mai haske ba tare da aiki ba. Bayan annashuwa mai haske, saman bututun ƙarfe yana riƙe da ainihin ƙarfe na ƙarfe, kuma an sami fili mai haske kusa da saman madubi. A ƙarƙashin buƙatun gabaɗaya, ana iya amfani da saman kai tsaye ba tare da aiki ba.

Domin mai haske annealing ya zama tasiri, Mun yi tube saman da tsabta da kuma free daga kasashen waje al'amari kafin annealing. Kuma mun ci gaba da tanderun annealing yanayi ne in mun gwada da free of oxygen (idan an so sakamako mai haske). Ana samun wannan ta hanyar cire kusan dukkanin iskar gas (ƙirƙirar vacuum) ko ta hanyar maye gurbin oxygen da nitrogen tare da busassun hydrogen ko argon.

Vacuum mai haske annealing yana samar da bututu mai tsabta sosai. Wannan bututu ya dace da buƙatun don layukan samar da iskar gas mai tsafta kamar su santsi na ciki, tsabta, ingantaccen juriya na lalata da rage iskar gas da barbashi daga ƙarfe.

Ana amfani da samfuran a cikin ingantattun kayan aiki, kayan aikin likita, masana'antar semiconductor babban bututun mai tsabta, bututun mota, bututun iskar gas, sararin samaniya da sarkar masana'antar hydrogen (ƙananan matsa lamba, matsa lamba, matsa lamba) matsananciyar matsa lamba (UHP) bututun bakin karfe da sauran filayen.

Muna kuma da sama da mita 100,000 na kayan bututu, wanda zai iya saduwa da abokan ciniki tare da lokutan isarwa cikin gaggawa.

Matsayin Material

| UNS | ASTM | EN |

| Saukewa: S30400/S30403 | 304/304L | 1.4301/1.4307 |

| S31603 | 316l | 1.4404 |

| S31635 | 316 Ti | 1.4571 |

| S32100 | 321 | 1.4541 |

| S34700 | 347 | 1.4550 |

| S31008 | 310S | 1.4845 |

| N08904 | 904l | 1.4539 |

| S32750 | 1.441 | |

| S31803 | 1.4462 | |

| S32205 | 1.4462 |

Ƙayyadaddun bayanai

ASTM A213 / ASTM A269/ASTM A789/EN10216-5 TC1 ko kamar yadda ake buƙata.

Tauri & Tauri

| Matsayin Samfura | Tashin Ciki | OD Surface | Hardness max | ||

| Nau'i na 1 | Nau'i na 2 | Nau'i na 3 | Nau'in | HRB | |

| ASTM A269 | Ra ≤ 0.35μm | Ra ≤ 0.6μm | Babu bukata | Yaren mutanen Poland makanikai | 90 |

Tsari

Cold mirgina / sanyi zane / Annealing.

Shiryawa

Kowane bututu guda wanda aka rufe a kan iyakar biyu, an cika shi a cikin jakunkuna mai tsabta guda ɗaya kuma na ƙarshe cikin akwati na katako.

Aikace-aikace

Chemical da petrochemical / Power da makamashi / Heat Exchanger masana'antu / Na'ura mai aiki da karfin ruwa da inji tsarin / Tsaftace jigilar iskar gas

Certificate na Daraja

ISO9001/2015 Standard

ISO 45001/2018 Standard

Takaddun shaida na PED

Takaddun gwajin dacewa na TUV Hydrogen

FAQ

- Cikakken Annealing.

- Isothermal Annealing.

- Rashin Kammalawa.

- Spherification Annealing.

- Yaduwa, ko Uniform, Annealing.

- Taimakon Danniya.

- Recrystalization Annealing.

Annealing wani tsari ne na maganin zafi wanda ke canza yanayin jiki da kuma wani lokacin har ma da sinadarai na abu don ƙara ductility da kuma rage taurin don sa ya zama mai aiki. Tsarin cirewa yana buƙatar kayan da ke sama da zazzabi na recrystallization na adadin lokaci kafin sanyaya.

Annealing wani tsari ne na maganin zafi da ake amfani da shi don canza kaddarorin karafa da sauran kayan, yawanci don sanya su su yi laushi, mafi ƙwanƙwasa, da ƙarancin karyewa. Ya ƙunshi dumama kayan zuwa takamaiman zafin jiki sannan kuma sanyaya shi a hankali a cikin hanyar sarrafawa, don sarrafa tsarin crystalline.

| A'a. | Girman (mm) | Girman EP Tube(316L). An lura da ● | |

| OD | Thk | ||

| BA Tube Inner surface roughness Ra0.35 | |||

| 1/4" | 6.35 | 0.89 | ● |

| 6.35 | 1.00 | ● | |

| 3/8" | 9.53 | 0.89 | ● |

| 9.53 | 1.00 | ||

| 1/2” | 12.70 | 0.89 | |

| 12.70 | 1.00 | ||

| 12.70 | 1.24 | ● | |

| 3/4” | 19.05 | 1.65 | ● |

| 1 | 25.40 | 1.65 | ● |

| BA Tube Inner surface roughness Ra0.6 | |||

| 1/8" | 3.175 | 0.71 | |

| 1/4" | 6.35 | 0.89 | |

| 3/8" | 9.53 | 0.89 | |

| 9.53 | 1.00 | ||

| 9.53 | 1.24 | ||

| 9.53 | 1.65 | ||

| 9.53 | 2.11 | ||

| 9.53 | 3.18 | ||

| 1/2" | 12.70 | 0.89 | |

| 12.70 | 1.00 | ||

| 12.70 | 1.24 | ||

| 12.70 | 1.65 | ||

| 12.70 | 2.11 | ||

| 5/8" | 15.88 | 1.24 | |

| 15.88 | 1.65 | ||

| 3/4" | 19.05 | 1.24 | |

| 19.05 | 1.65 | ||

| 19.05 | 2.11 | ||

| 1" | 25.40 | 1.24 | |

| 25.40 | 1.65 | ||

| 25.40 | 2.11 | ||

| 1-1/4" | 31.75 | 1.65 | ● |

| 1-1/2" | 38.10 | 1.65 | ● |

| 2" | 50.80 | 1.65 | ● |

| 10 A | 17.30 | 1.20 | ● |

| 15 A | 21.70 | 1.65 | ● |

| 20 A | 27.20 | 1.65 | ● |

| 25 A | 34.00 | 1.65 | ● |

| 32A | 42.70 | 1.65 | ● |

| 40A | 48.60 | 1.65 | ● |

| 50A | 60.50 | 1.65 | |

| 8.00 | 1.00 | ||

| 8.00 | 1.50 | ||

| 10.00 | 1.00 | ||

| 10.00 | 1.50 | ||

| 10.00 | 2.00 | ||

| 12.00 | 1.00 | ||

| 12.00 | 1.50 | ||

| 12.00 | 2.00 | ||

| 14.00 | 1.00 | ||

| 14.00 | 1.50 | ||

| 14.00 | 2.00 | ||

| 15.00 | 1.00 | ||

| 15.00 | 1.50 | ||

| 15.00 | 2.00 | ||

| 16.00 | 1.00 | ||

| 16.00 | 1.50 | ||

| 16.00 | 2.00 | ||

| 18.00 | 1.00 | ||

| 18.00 | 1.50 | ||

| 18.00 | 2.00 | ||

| 19.00 | 1.50 | ||

| 19.00 | 2.00 | ||

| 20.00 | 1.50 | ||

| 20.00 | 2.00 | ||

| 22.00 | 1.50 | ||

| 22.00 | 2.00 | ||

| 25.00 | 2.00 | ||

| 28.00 | 1.50 | ||

| BA Tube , Babu buƙatu game da rashin ƙarfi na ciki | |||

| 1/4" | 6.35 | 0.89 | |

| 6.35 | 1.24 | ||

| 6.35 | 1.65 | ||

| 3/8" | 9.53 | 0.89 | |

| 9.53 | 1.24 | ||

| 9.53 | 1.65 | ||

| 9.53 | 2.11 | ||

| 1/2" | 12.70 | 0.89 | |

| 12.70 | 1.24 | ||

| 12.70 | 1.65 | ||

| 12.70 | 2.11 | ||

| 6.00 | 1.00 | ||

| 8.00 | 1.00 | ||

| 10.00 | 1.00 | ||

| 12.00 | 1.00 | ||

| 12.00 | 1.50 | ||